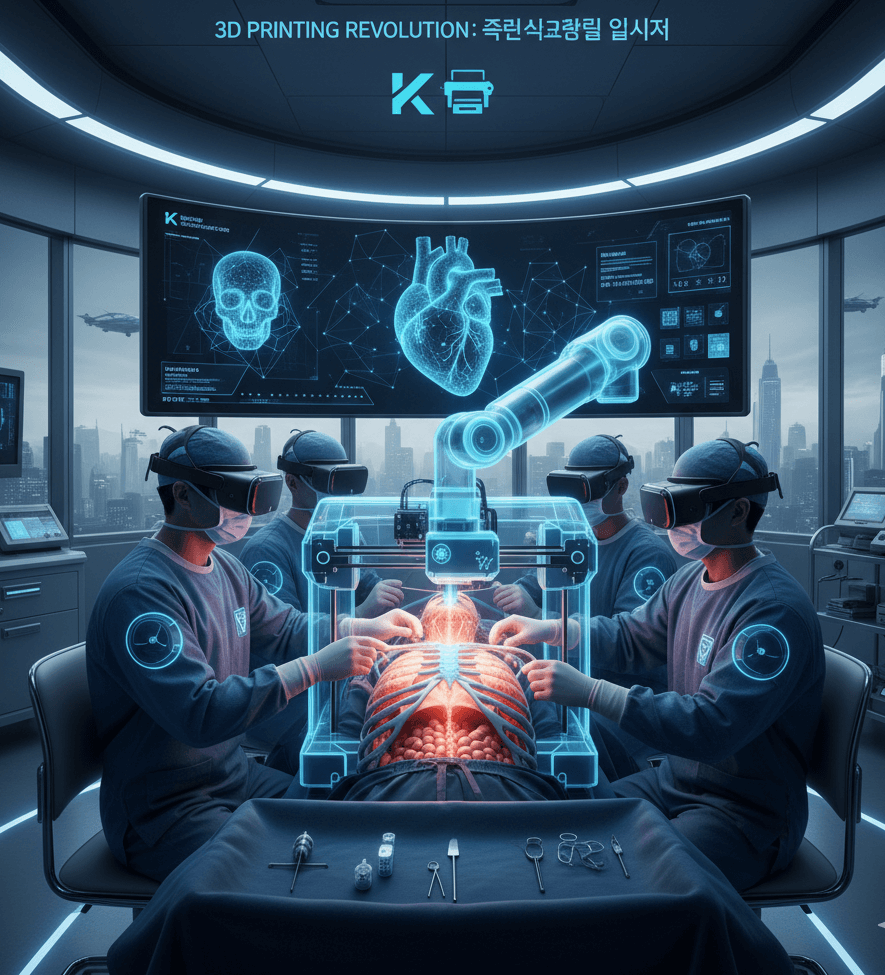

3D printing technology is transforming modern medicine, and Korea is at the forefront of using it to reshape surgical innovation. From personalized implants and surgical planning to bioprinted organs and real-time printing in the operating room, Korean hospitals and researchers are redefining precision and patient care.

Personalized Models for Surgical Planning

Korean surgeons are increasingly using 3D-printed anatomical models based on CT and MRI scans to prepare for complex surgeries. These models replicate each patient’s unique anatomy, allowing surgeons to plan incisions, rehearse procedures, and reduce operating time. For example, in congenital heart or craniofacial surgeries, 3D-printed replicas help doctors anticipate complications before entering the operating room.

These realistic models also play a crucial role in medical education, enabling students and residents to practice intricate procedures safely. By turning digital scans into tangible training tools, 3D printing bridges the gap between theory and practice.

Custom Implants and Bone Reconstruction

In orthopedic and reconstructive surgery, 3D printing allows the creation of custom-made implants that perfectly match a patient’s bone structure. Surgeons can design and print replacement parts for damaged bones, joints, or facial structures. Materials like titanium and biocompatible polymers are shaped precisely for each individual, improving comfort and healing outcomes.

For instance, Korean hospitals have successfully performed jaw, pelvic, and skull reconstructions using 3D-printed implants. These custom components reduce the risk of misalignment and infection, shorten surgery time, and often lead to faster recovery.

Bioprinting: A New Era in Organ Replacement

Korean scientists have achieved major breakthroughs in bioprinting, the process of printing living tissue. A milestone achievement came when a team successfully implanted a 3D-bioprinted trachea into a patient who had lost part of her airway due to cancer surgery. The artificial organ was created using a combination of stem cells and biodegradable materials.

This groundbreaking operation marked the world’s first clinical use of a bioprinted organ, proving that 3D printing can move beyond prosthetics into real tissue replacement. Researchers are now experimenting with printing other body parts, including cartilage, skin, and small organ patches.

Intraoperative 3D Printing and Real-Time Surgery

Korean universities and hospitals are exploring on-the-spot printing techniques that allow surgeons to produce implants or bone grafts during surgery. A notable example is the development of a handheld 3D-printing device that functions like a “medical glue gun,” allowing surgeons to deposit biocompatible materials directly onto damaged bone structures.

This real-time printing technology offers the ability to customize repairs inside the operating room, eliminating the need for pre-manufactured parts. It also allows for adjustments based on the patient’s anatomy as observed during surgery.

Advancing Surgical Guides and 4D Printing

Beyond static implants, Korean researchers are experimenting with 4D printing—where printed materials can change shape over time or adapt to body temperature and movement. For example, a newly designed surgical guide for kidney cancer can contract and expand once inside the body, allowing minimally invasive surgery through smaller incisions.

3D printing is also improving the accuracy of surgical cutting guides used in orthopedic and dental procedures. These guides help surgeons make precise cuts, align bones accurately, and ensure optimal implant placement.

Benefits for Surgeons and Patients

The use of 3D printing in surgery provides multiple advantages:

- Precision: Tailored implants and surgical guides enhance accuracy.

- Shorter Operations: Preoperative planning reduces surgery duration and anesthesia time.

- Better Outcomes: Personalized implants fit perfectly, improving healing and mobility.

- Educational Value: Surgeons and students can practice complex cases using printed models.

- Innovation: Hospitals adopting these technologies attract top medical talent and research funding.

Challenges and Considerations

Despite its promise, 3D printing in medicine still faces challenges. Regulatory approval for bioprinted organs and implants requires extensive safety testing. Printing living tissues like blood vessels and soft organs remains scientifically complex. Costs can also be high, limiting access for smaller hospitals.

There are also material and technical limitations—for instance, printed structures must withstand sterilization and maintain accuracy at microscopic levels. Nonetheless, ongoing government and industry support is helping Korean researchers overcome these hurdles.

The Future of 3D Printing in Korean Medicine

Korea is rapidly advancing toward a new era of personalized surgery. The next steps include:

- Expanding clinical trials for bioprinted organs and cartilage repair.

- Developing smart biomaterials that integrate naturally with the body.

- Introducing AI-assisted design to automate custom implant creation.

- Bringing 3D-printing technology into regional hospitals for broader accessibility.

- Establishing national safety and quality standards for printed medical devices.

As these innovations mature, Korea is poised to become a global leader in medical 3D printing. From custom implants to living organs, this technology is transforming the meaning of surgery—making it faster, safer, and more personal than ever before.